Jak wybrać klamkę uchylną?

Wybór idealnej klamki uchylnej do drzwi może być nie lada wyzwaniem. Dostępność szerokiej gamy modeli, stylów i materiałów na rynku sprawia, że decyzja ta staje się jeszcze trudniejsza. Czy powinniśm...

Wybór idealnej klamki uchylnej do drzwi może być nie lada wyzwaniem. Dostępność szerokiej gamy modeli, stylów i materiałów na rynku sprawia, że decyzja ta staje się jeszcze trudniejsza. Czy powinniśm...

Kredyty frankowe były kiedyś atrakcyjną alternatywą dla wielu Polaków, w tym również dla mieszkańców Gdańska. Niskie stopy procentowe, korzystne warunki – kto by się oparł takiej pokusie? Lecz niestet...

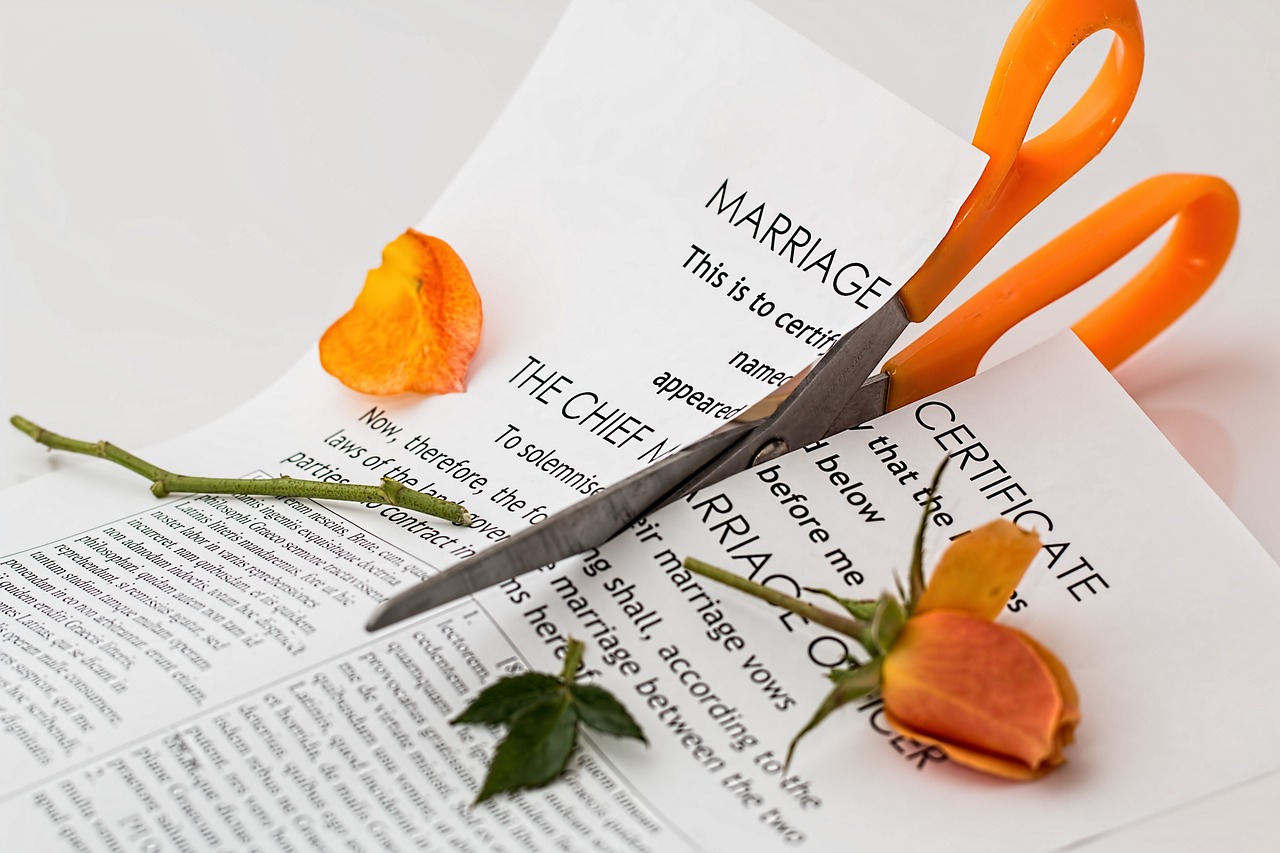

Zanurzeni w burzy miłości i ekscytacji, Monika i Adam nieustannie powtarzają, że ich miłość jest wyjątkowa. Ich serca biją harmonijnie, a przyszłość wydaje się przepasana uczuciem. Teraz kiedy przekro...

Każdy z nas może znaleźć się w sytuacji, w której konieczna jest pomoc prawnika. Bez względu na to, czy to kwestia rozwiązania problemów prawnych, sporów sądowych czy załatwienia ważnych dokumentów, w...

Świat ortodoncji, dla jednych fascynujący, dla innych nawet tajemniczy, kryje w sobie wiele zagadek i rozwiązań, które dla przeciętnego człowieka niezwiązanego z branżą mogą wydawać się niemal niezroz...

Pomysł na uśmiech z zębów jak z reklamy? Marzenia o idealnym zgryzie, które przekładają się na zwiększoną pewność siebie i udane społeczne interakcje? Aparat samoligaturujący może być odpowiedzią na t...

Co to znaczy termoizolacja? Czy to kolejne zagadkowe słowo z branży budowlanej, które dla większości z nas brzmi jak czarna magia? Nic bardziej mylnego. Zdecydowanie warto poznać bliżej ten temat, pon...

W świecie pełnym produktów, konsumenckim labiryncie ofert, opakowania z folii mono, jak te dostępne na stronie https://plastmoroz.pl/opakowania-z-folii-mono.html, przyciągają uwagę swoją prostotą i fu...

Budowa obiektów przemysłowych czy magazynowych to duża inwestycja, która nie tylko zajmuje sporo czasu, a także pochłania sporo pieniędzy. Od jakości konstrukcji zależy jego wytrzymałość, a przecież b...

Pozycjonowanie stron internetowych stało się nieodłącznym elementem strategii marketingowych w erze cyfrowej. Dążenie do osiągnięcia wysokiej pozycji w wyszukiwarkach jest kluczowe dla zwiększenia wid...

Pompa ciepła to innowacyjne rozwiązanie, które znacząco wpływa na efektywność energetyczną budynku. Jest to urządzenie, które wykorzystuje energię z otoczenia do ogrzewania lub chłodzenia pomieszczeń....

Jedno jest pewne: zegarki to więcej niż tylko praktyczne narzędzia. Są to elementy, które dopełniają naszą codzienną stylizację, podkreślają nasz charakter i status społeczny. Wśród nich zegarek Tisso...